Why do PCB boards need Conformal coating ?

Moisture is the most prevalent and destructive factor for PCBs. Excessive moisture will greatly reduce the insulation resistance between the conductor, accelerate the high-speed decomposition, reduce the Q value, and corrosion of the conductor. We often see the metal part of the PCB circuit board up the copper green is not coated with three anti-varnish metal copper and water vapour, oxygen and its chemical reaction caused by the common.

And in the printed circuit boards on the hundreds of randomly found pollutants have the same destructive power. They can lead to the same results as moisture erosion - electronic decay, corrosion of conductors and even cause irreparable short circuits. The most common contaminants found in electrical systems are probably chemicals left over from the manufacturing process. Examples of these contaminants are fluxes, solvent release agents, metal particles and marker inks. There are also major groups of contaminants that can be caused by inadvertent human handling, such as body oils, fingerprints, cosmetics and food residues. There are also many pollutants in the operating environment, such as salt spray, sand, fuel, acid, and other corrosive vapours and mould.

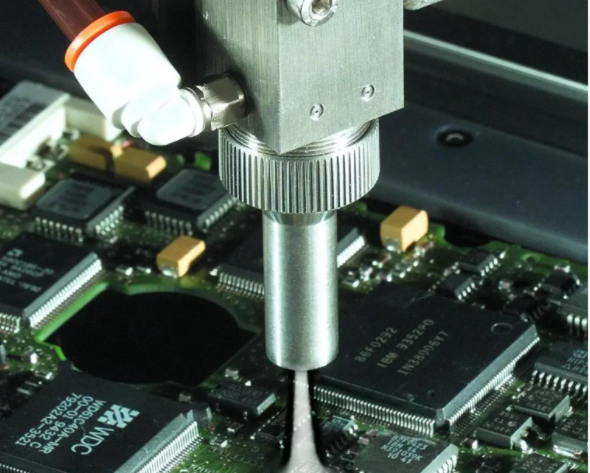

Coating printed circuit boards and components with Conformal coating reduces or eliminates the degradation of electronic performance when they may be subjected to unfavourable factors in the operating environment. The purpose of the coating is considered to be fulfilled if the coating maintains its effect for a satisfactory period of time, e.g., longer than the useful life of the product.

Even if the coating layer is thin, it is still able to withstand mechanical vibration and oscillation, thermal shock, and operation at high temperatures to a certain extent. Of course, the notion that film can be used to provide mechanical strength or sufficient insulation for the individual components inserted on a printed circuit board is false. Components must be mechanically inserted and must have their own suitable caulking so that there is double insurance against accidents.

Conformal coating (common lamination) is a specially formulated coating used to protect circuit boards and their associated equipment from the erosion of bad conditions, thereby improving and extending their service life and ensuring the safety and reliability of use.

The three defences are: humidity, salt spray and static electricity. Common lamination is a very thin protective layer of electronic circuits and components, which can enhance the moisture and dirt resistance of electronic circuits and components and prevent solder joints and conductors from erosion, but also can play a role in shielding and eliminating electromagnetic interference and preventing line short-circuit, and to improve the insulation properties of the circuit board.

In addition, the coating of the protective film is also conducive to the line and components of the abrasion and solvent resistance, and can release the pressure caused by cyclical changes in temperature.

Electronic equipment working in the field, aerospace, marine and other harsh environmental conditions, the circuit substrate is susceptible to moisture, salt spray, mould and the impact of the system failure, therefore, the circuit substrate of the Conformal coating technology has become a process technology of great concern in the field of electronic assembly.

In real conditions, such as chemical, vibration, high dust, salt spray, humidity and high temperature environment, the circuit board may produce corrosion, softening, deformation, mould and other problems, resulting in circuit board circuit failure. Three-proof paint coated on the surface of the circuit board to form a layer of Conformal coating film (three-proof refers to moisture-proof, anti-salt spray, anti-mould).

1, Civil and commercial applications Conformal coating can provide protection for electronic circuits in household appliances, so that they can resist: such as: water, moisture, insects, office and home in the harmful substances.

Such as: soya milk machine, coffee machine, induction cooker, dryer, dishwasher, air-conditioning, computer, bathroom electronics, electric cars.

2, The automotive industry The automotive industry requires three-proof paint to protect circuits from the following hazards, such as: petrol evaporation, salt spray, brake fluid, and so on. The application of electronic systems in automobiles continues to grow rapidly, so the use of three-proof paint has become a basic requirement to ensure that the long-term reliability of automotive electronics.

Such as: computer control systems, air conditioning, automotive electronics.

3, Aerospace as a result of the specificity of the use of the environment, aviation, aerospace environment on the electronic equipment requirements are stringent, especially in the rapid pressurisation, depressurisation conditions, but also to maintain good circuit performance. Conformal coating pressure stability is therefore widely used.

Such as: star system, military control system, flight line control system.

4、Navigation Whether it is fresh fresh water or salty seawater, it will cause harm to the electrical circuits of marine equipment. The use of Conformal coating can maximise the protection of equipment on the water surface and even submerged and underwater.

Such as: navigation systems, radar control systems.

5, The electronics industry Conformal coatingt can protect electronic equipment from water, moisture, external chemicals and special use of environmental erosion, to ensure its continued stability, its application range is very broad.

Such as: LED display SMT chip processing, LED guardrail tube SMT chip processing, solar energy SMT chip processing, instrumentation SMT chip processing, power SMT chip processing, inverter SMT chip processing, consumer electronics SMT chip processing, anti-theft and fire alarm device SMT chip processing, etc.